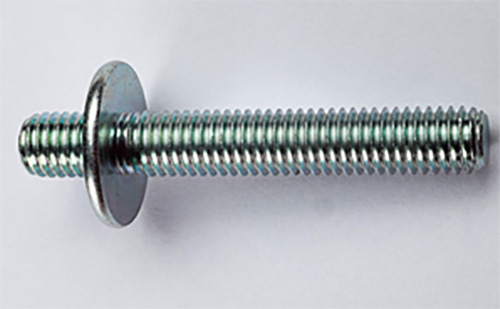

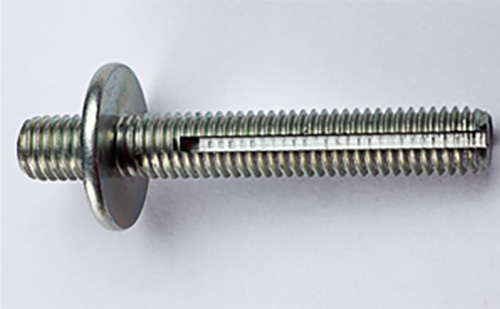

How are Klemm-tight carbon special thread locks made?

Klemm-tight®

A groove is milled into the screw thread and an elastic malleable special thread is cold pressed into it

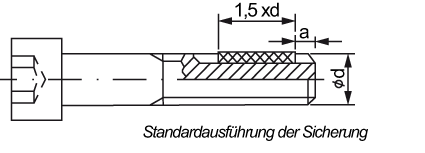

Design and positioning

Standard Dimensions according to DIN 267

Without specification the length of the locking element lies in a standard range of

1,5xd ± 2 P for P < 1 and 1,5xd ± P für P ≥ 1

P = Thread pitch measured from the screw-end

d = Nominal diameter of the screw

a = Position of the thread lock from the screw end

The first two or three threads have to be without locking system to make screwing-in easier.

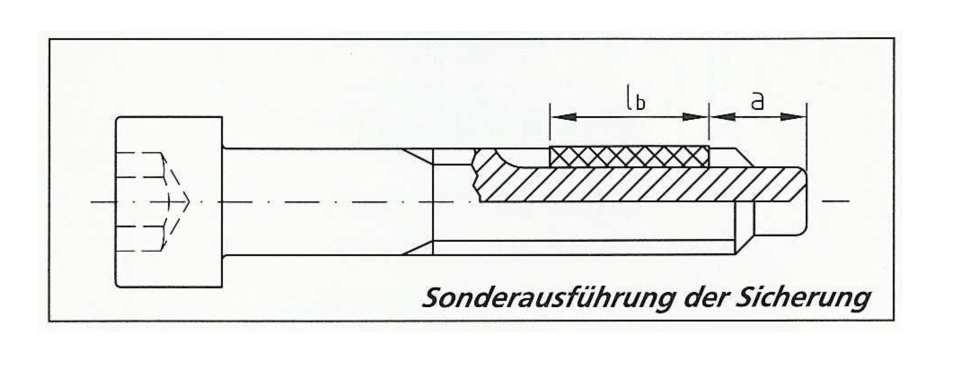

Version with special length and / or position

The measurements Ib are to be entered in the order.

l b = Length of the locking system

a = Distance of the thread lock from the screw end

For l b and a tolerances ± 2 P for P < 1 and ± P for P ≥ 1